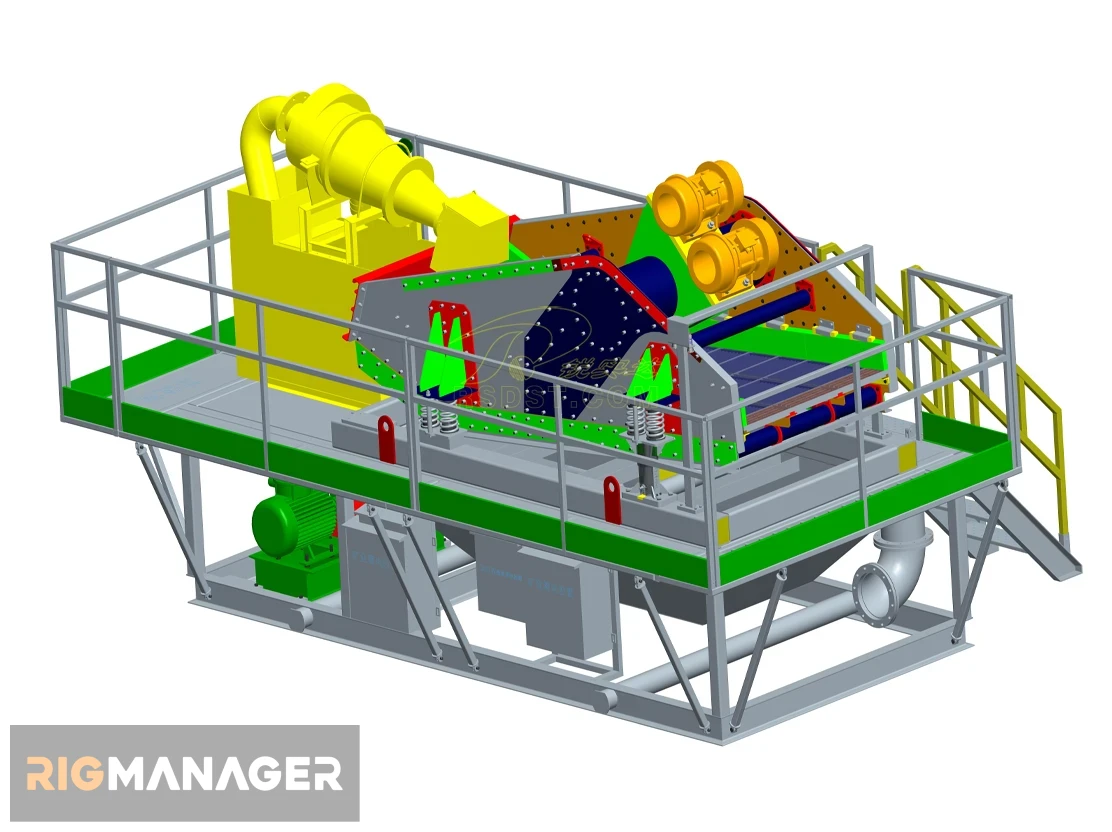

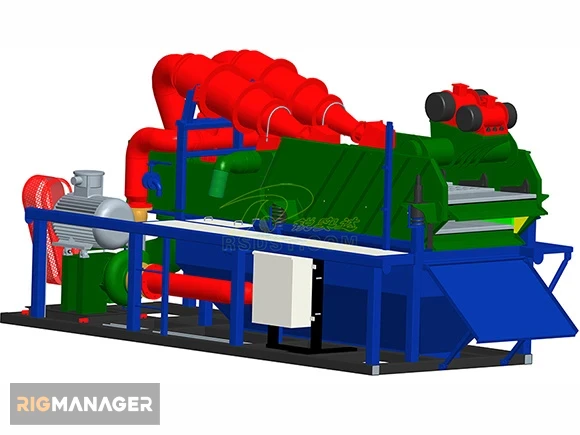

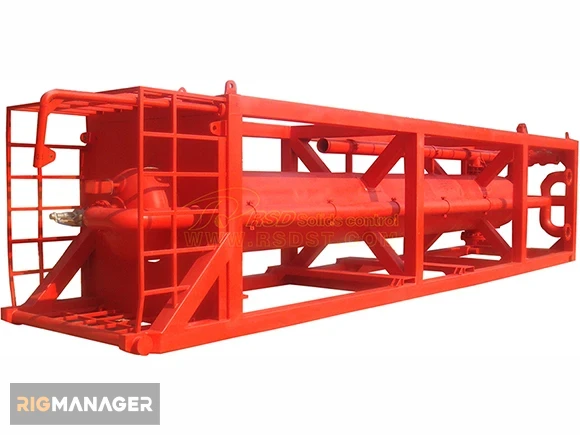

Compact Sand Washing Machine

- Our balance elliptical screening technology together with high performance cyclone improves the treatment capacity by more than 30%;

- Our laboratory station is ready for on-site experiments to meet your requirements;

- Our laboratory wastewater can be directly discharged after treatment.Fine sand recovery machine is also known as tailings sand recovery machine, fine sand extraction machine, fine sand collection machine, sand separator, mud separator, sand and water mixture treatment system, etc.Summary

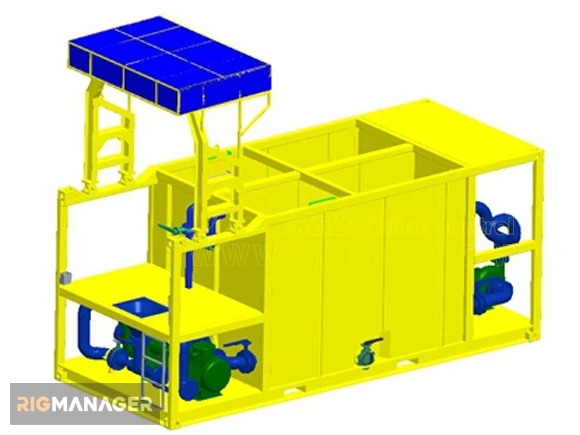

Summary: The Compact Sand Washing Machine is developed for dewatering, demediating and desliming of slurry materials. The biggest characteristic of this machine is that it can well solve the problem of fine sand loss in sand making industry.

Compact Sand Washing Machine is also known as tailings sand recovery machine, fine sand extraction machine, fine sand collection machine, sand separator, mud separator, sand and water mixture treatment system, etc.

Working process: the slurry sand water mixture is pumped to the high-pressure sand separator, and the tailings concentrated by centrifugal classification are provided to the dehydration screen through the sand settling nozzle. After being dehydrated by the dehydration screen, the tailings and water are effectively separated, and a small amount of tailings and mud are returned to the cleaning tank through the return tank. When the liquid level of the cleaning tank is too high, they are discharged through the discharge port.

The concentration of reclaimed material by weight of dehydration sieve is 70%-85%.

The fineness modulus can be adjusted by changing the pump speed, changing the mortar concentration, adjusting the overflow amount and replacing the mortar nozzle.

Thus complete cleaning, dehydration and classification of three functions.

Technology comprehensive commentary:

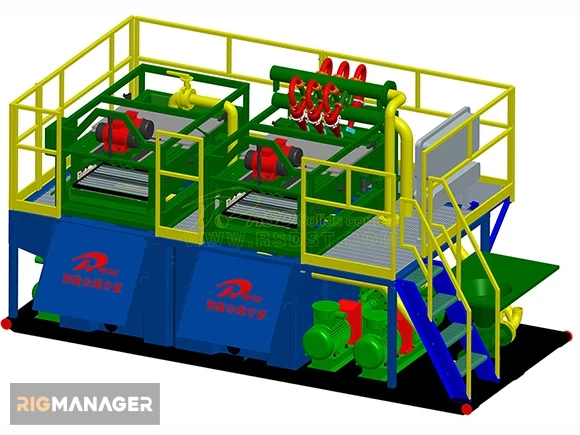

- Adopts balance ellipse technology to achieve a better separation effectiveness.

- Adopts variable motion technology ,which can adjust the motion automatically according to feeding condition of materials.

- Testing in advance is available for each material, and solution can be designed specially according to different material nature to enhance the comprehensive operation effectiveness.

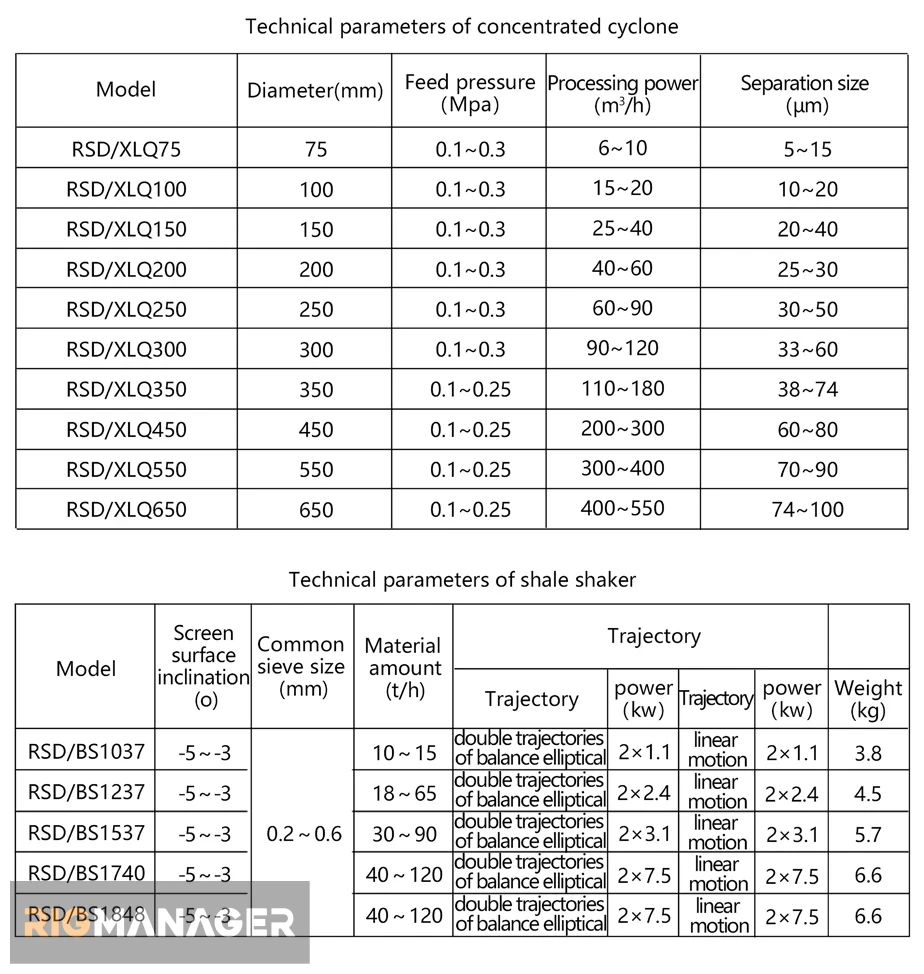

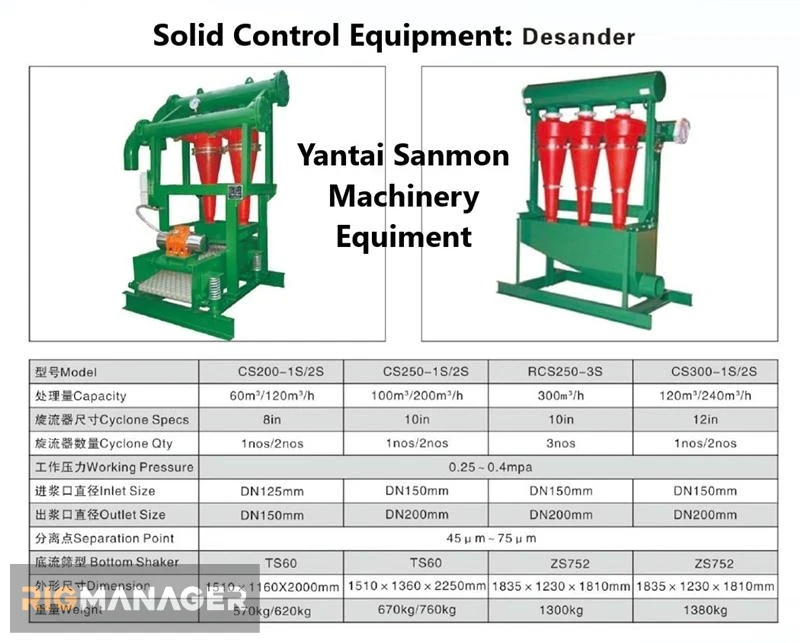

Technical parameter:

See table in attached images.

Technical features

- The fine sand recovery machine of Restar, according to user requirements for processing capacity and grading granularity matching design.

- The equipment of small low power consumption, less wearing parts, convenient maintenance;According to the situation of the site, the combination of multiple units, to reach the processing scale.

- According to user requirements and recommend the condition of material matching motioned elliptical trajectory solution and straight trajectory in order to solve the paste screen, the screen and the phenomenon of accumulated sand, improve equipment sieve permeability and discharging effect is good.

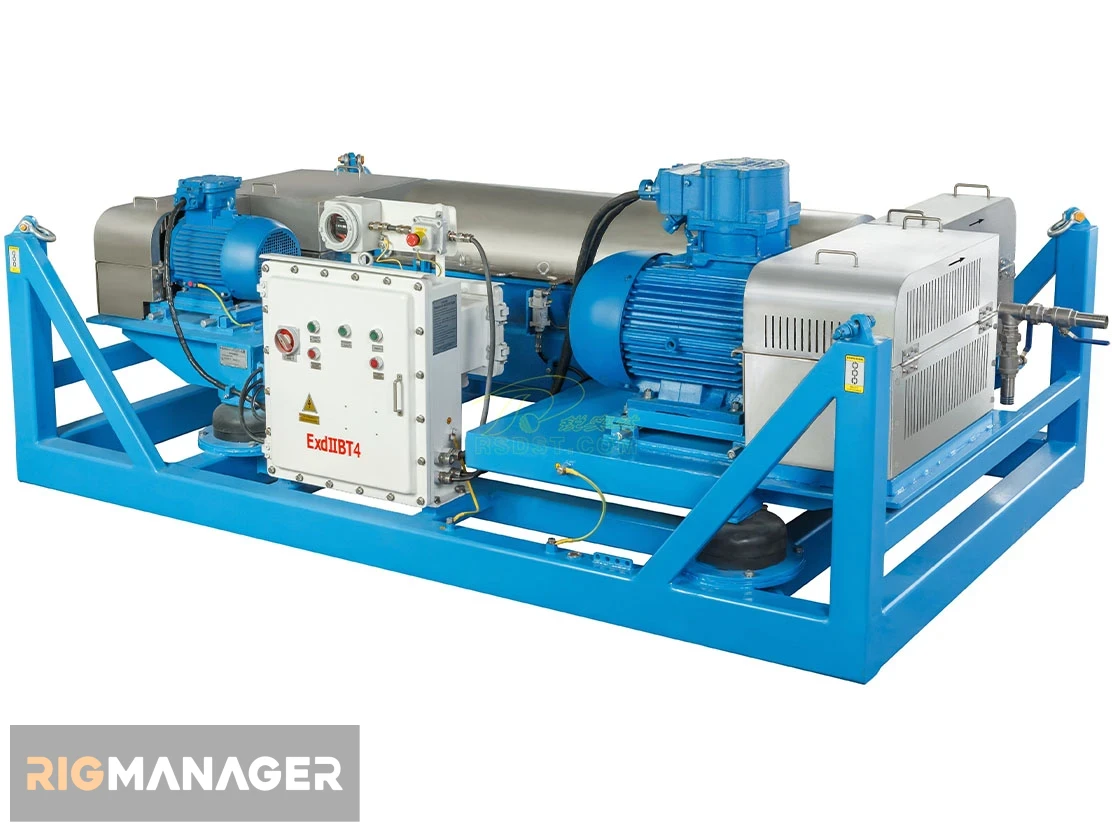

- Adopts frequency conversion control system, to adapt to the working condition of a wide range, using vacuum auxiliary dehydration screen can achieve the result of more dry.

- Splash proof system, electric dynamic adjustment Angle system makes the equipment operation is simple and clean.