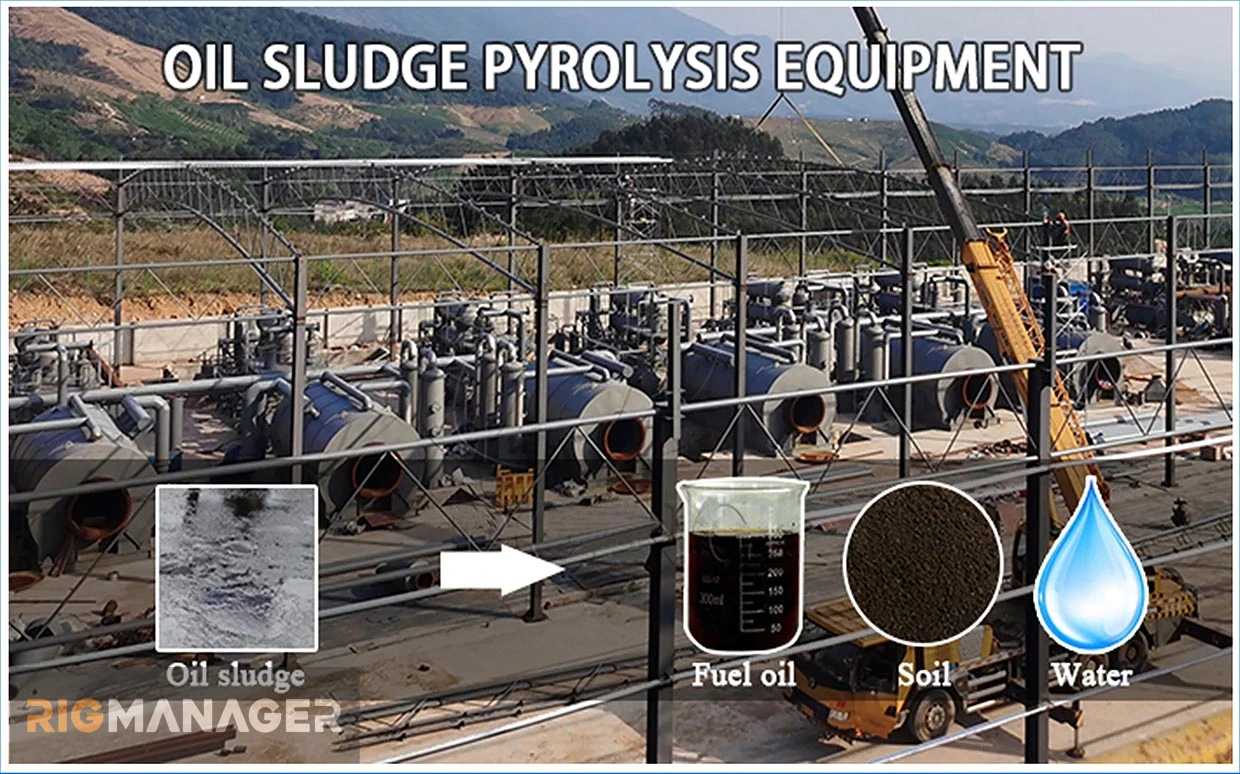

Oily waste thermal desorption equipment

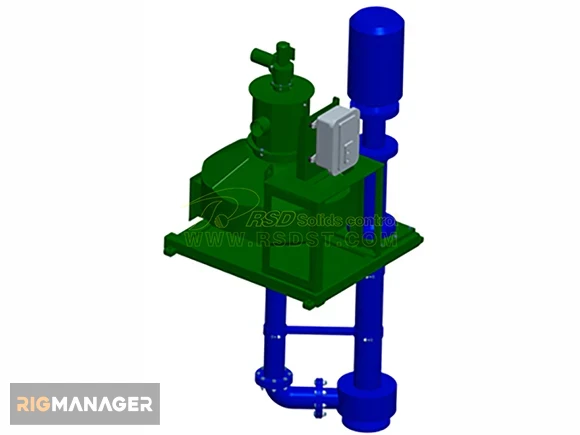

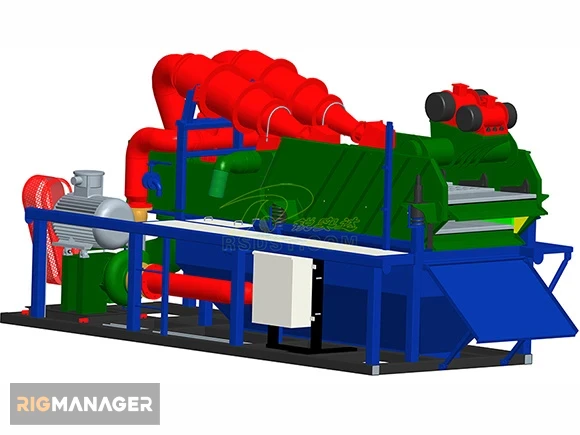

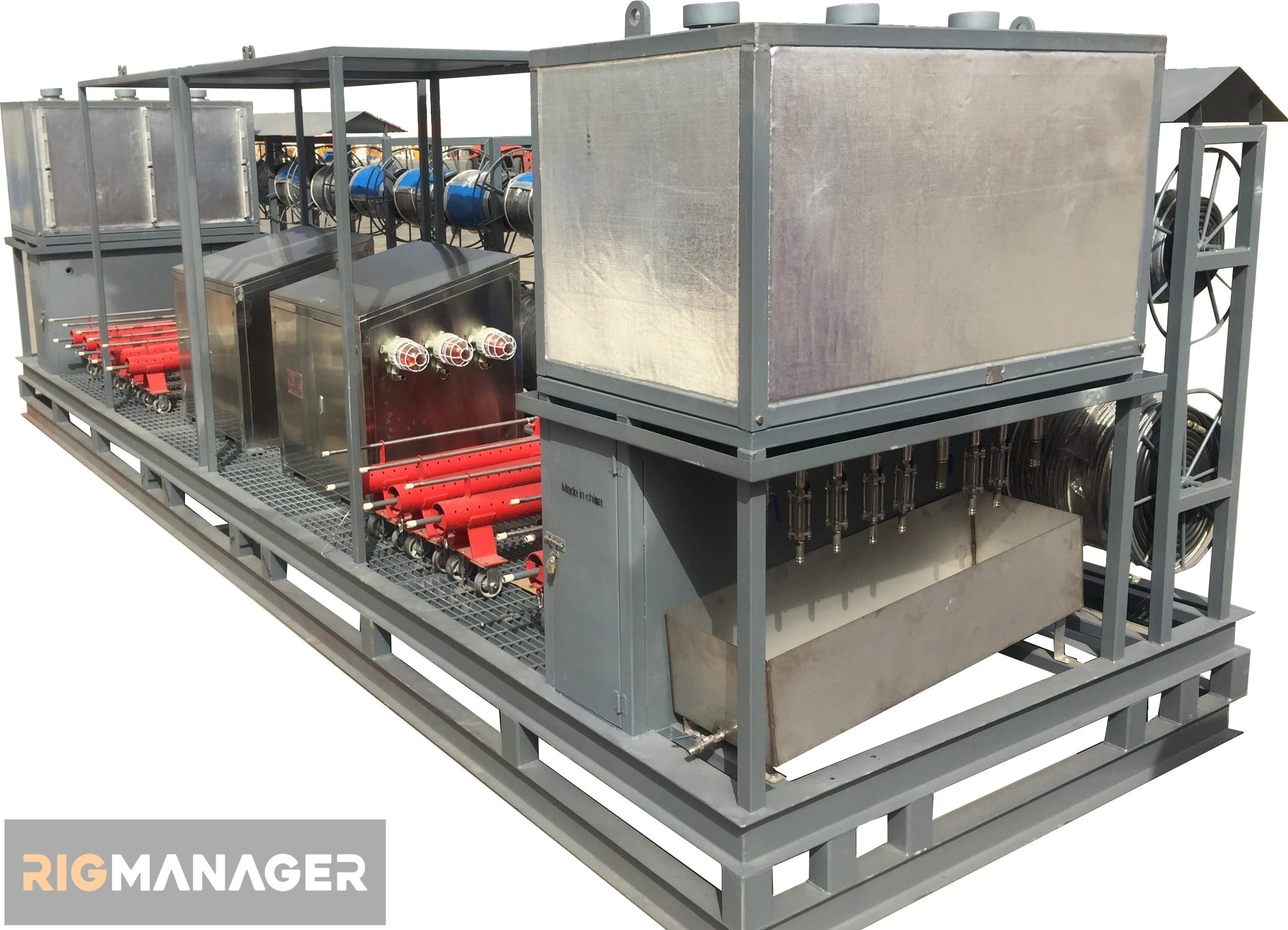

In the scheme, 6~8 units cracking kettles are adopted, and these equipment runs in series. The cracking furnace can run continuously without interruption. This system consists of hydraulic feed system, cracking carbonization system (rotary cracking furnace, non-condensable gas combustion system, low nitrogen gas combustion machine, steam generator, invalid exhaust chamber), cracking gas collection and processing system (atmolysis bag, spray cooler, oil-water separation devices).

Summarize

In the scheme, 6~8 units cracking kettles are adopted, and these equipment runs in series. The cracking furnace can run continuously without interruption.

This system consists of hydraulic feed system, cracking carbonization system (rotary cracking furnace, non-condensable gas combustion system, low nitrogen gas combustion machine, steam generator, invalid exhaust chamber), cracking gas collection and processing system (atmolysis bag, spray cooler, oil-water separation devices), flue gas purification processing system (column tube cooler, and the secondary atomization cooling desulfurization dusting tower, gas water Separator, activated carbon adsorption industrial purifier), tail gas collection and treatment system, auxiliary facilities, etc.

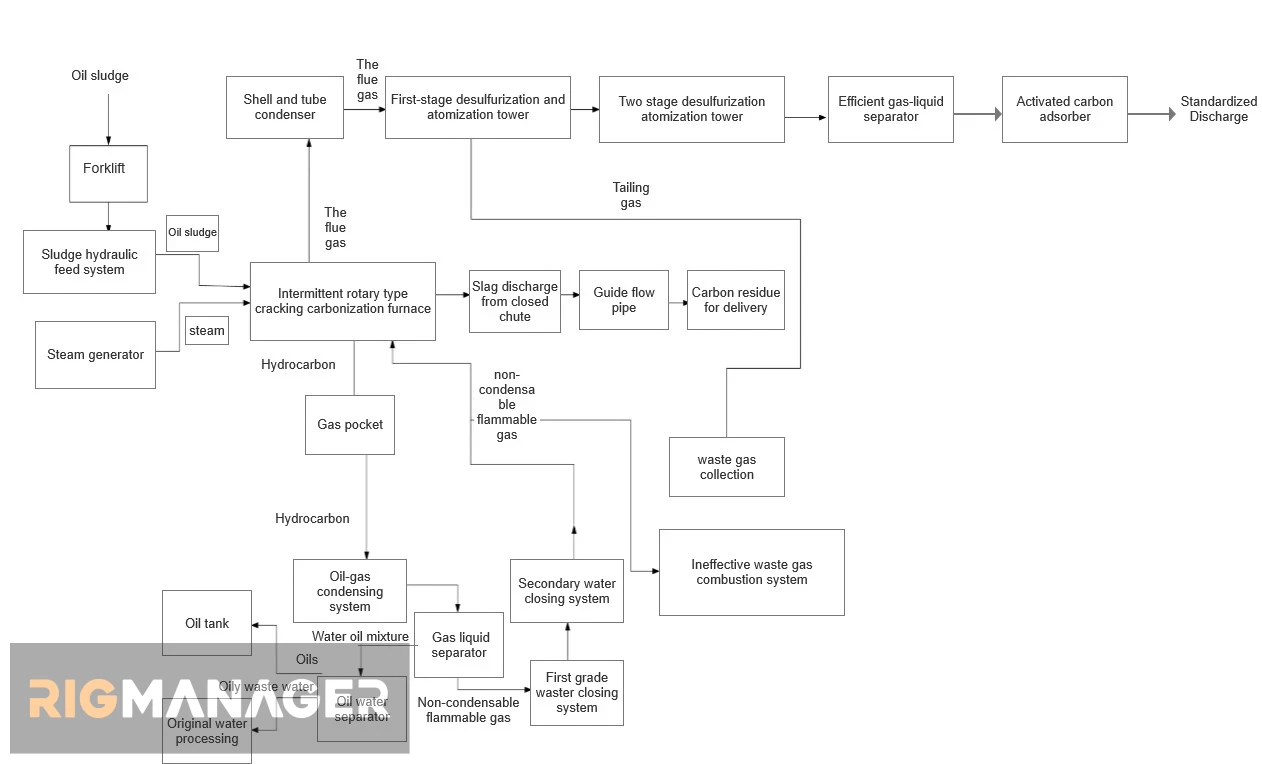

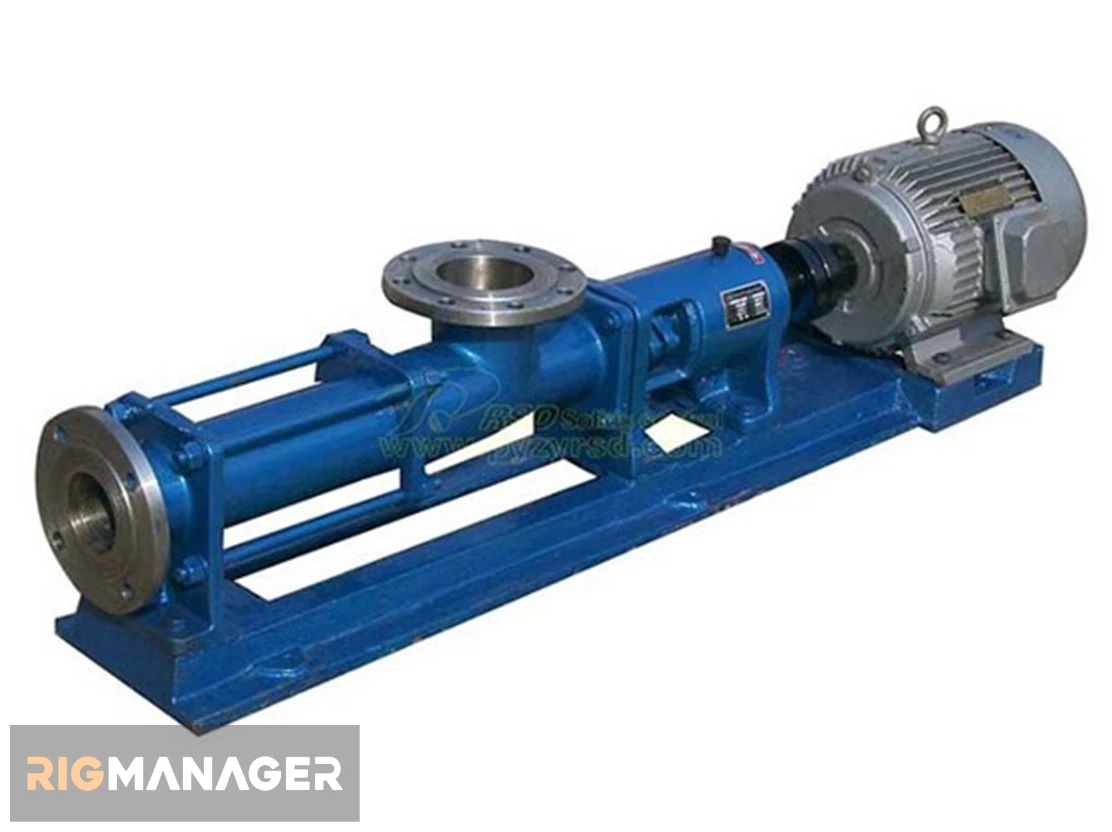

The raw oil sludge to be treated enters the intermittent rotary cracking carbonization furnace through the hydraulic feeding system through the forklift truck for thermal cracking. The cracking cracking gas enters the condensing system after passing through the gas separation package, and the oil-water mixture generated after condensation enters the gas-liquid separation tank.

The non-condensable cracking gas enters the furnace for combustion through the secondary safety water seal. If too much non-condensable gas cannot be burned in the furnace, the non-condensable cracking gas will be split into the invalid exhaust gas combustion chamber and ignited.

After the remaining liquid in the gas-liquid separation tank is separated by oil and water, the pyrolytic oil enters the oil tank and the waste water enters the water treatment unit.

After the cracking, the sludge is sent to the carbon black packing device through the closed chute slag discharging device and the guide pipe.

The whole cracking process is mainly provided by the natural gas burner, and the burned natural gas and non-condensable cracking gas after combustion are discharged through the pipe cooler, the first and second stage desulfurization and dust removal device, the gas-liquid separation device and the activated carbon adsorption device, and then through the induced draft fan through the chimney.

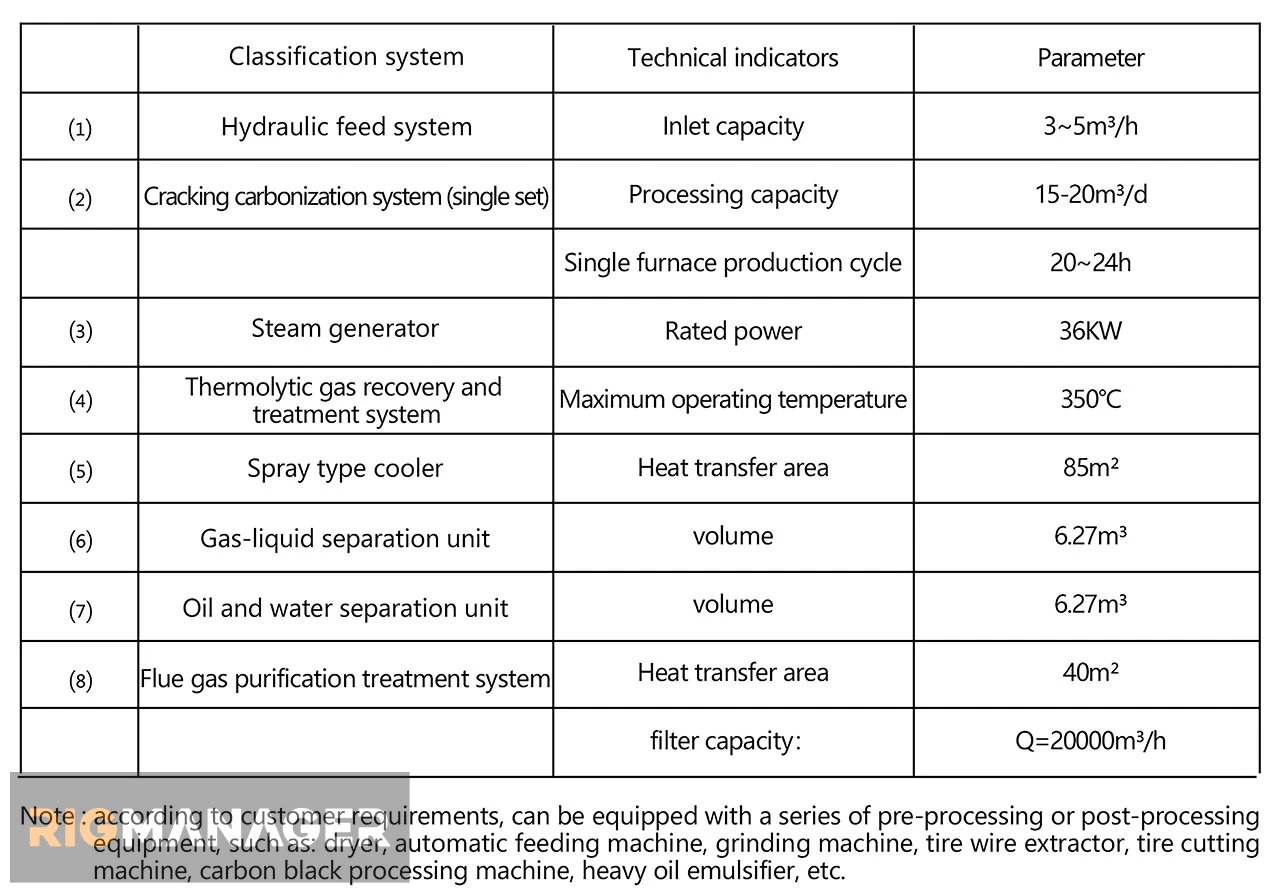

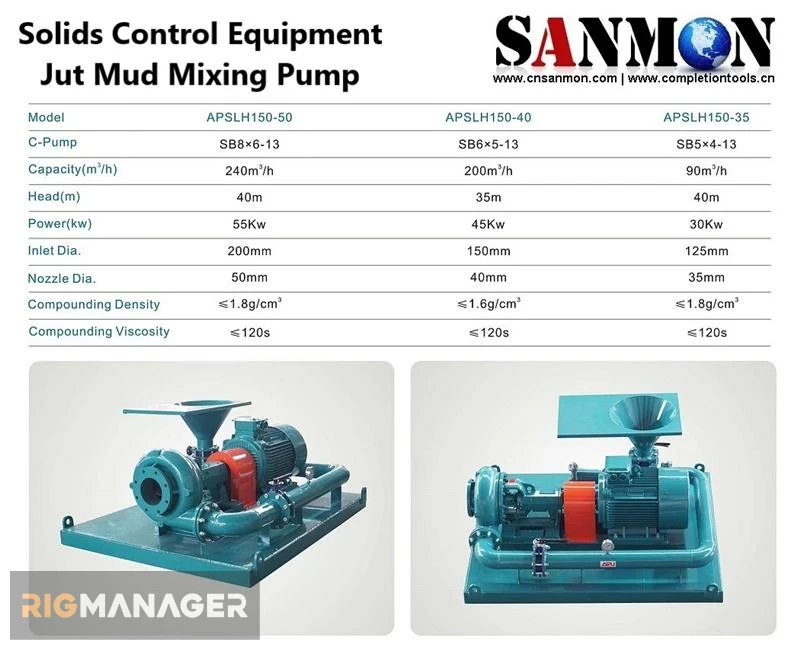

Equipment model and specification:

See table in attached images.

Technical features

- Unique oil splitting design, according to the oil density divided into light fuel oil, medium fuel oil, heavy fuel oil, to meet the requirements of customers for oil classification.

- The gas purification system specially designed for the developed countries in Europe and the United States, that is, the formation of micro negative pressure flue gas treatment, so that the production process more safe and reliable.

- Unique desulfurization and dust removal design: through spray, purification, adsorption can more effectively remove acid gas and dust, environmental protection and no pollution.

- Combined unit cracking equipment, automatic continuous production and operation can be realized, thus reducing operating costs and increasing profits.

- Applicable raw materials:Waste plastic, waste rubber, waste paint residue, electroplating sludge and other organic solid waste.

- Waste plastic, waste rubber, waste paint residue, electroplating sludge and other organic solid waste.

- No matter how high the water content and oil content is and how complex oil sludge is, after treatment, the oil content can be reduced to below 0.3% ,which meet the highest national environmental protection standards.

- This system adopt multiple units of alternating operation solution to recycle flue gas and achieve heat recovery and recycling with high heat utilization rate, effectively save operating costs. In addition, it's capacity design can be expanded infinitely basing on basic process unit to according to the user's working condition.