Drum type vacuum adsorption shaker

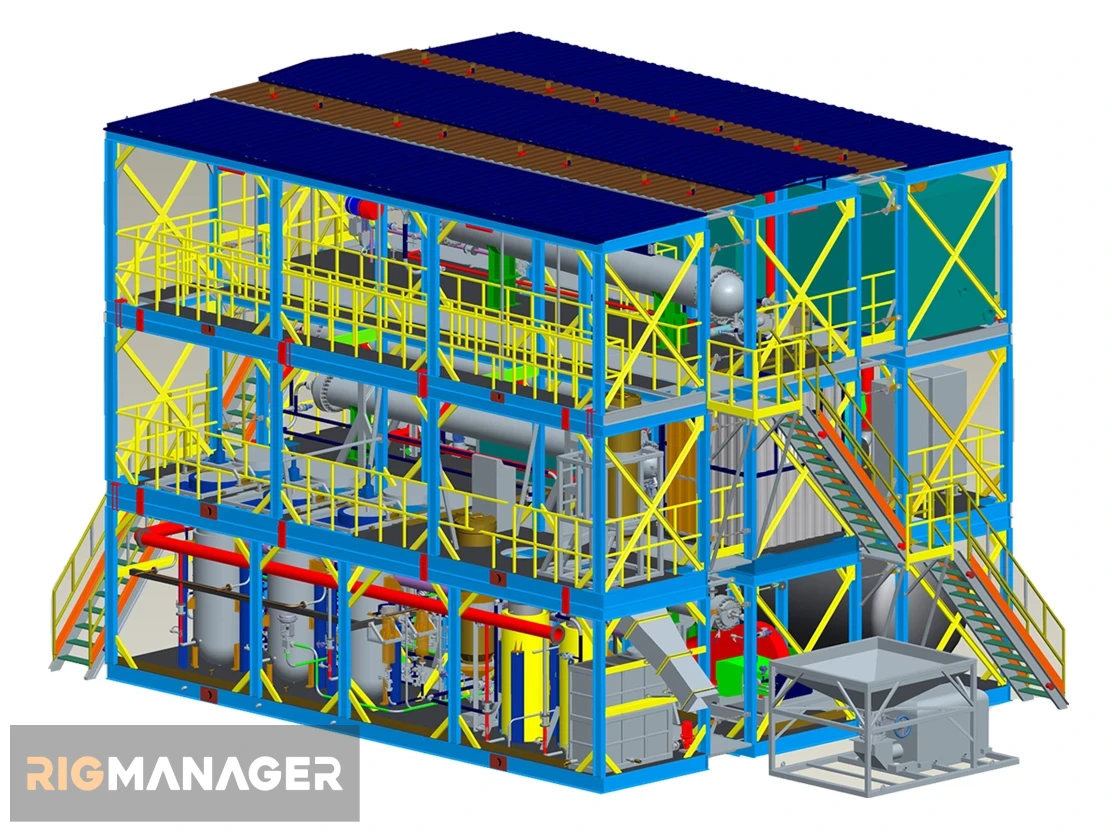

With vacuum generation device, it can recover drilling fluid efficiently under vacuum condition, and the recovery efficiency is high and the drilling cost is effectively saved.

Summary

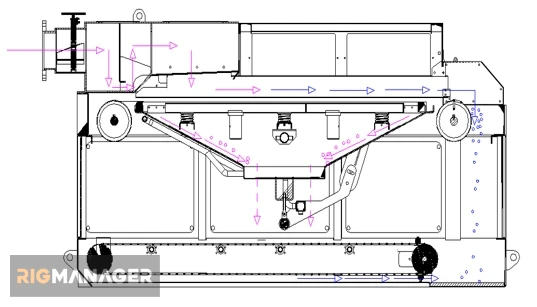

As the drilling fluid enters the rotary screen in the filtration area, the flow through the screen allows the fluid to be sucked through the screen into the lower collection tank and then into the vacuum drainage chamber. During this time, the shaker is able to continuously micro-vibrate the sieve, effectively improving the quality of the drilling fluid and helping to break the surface tension of the droplets to better penetrate the sieve. The material larger than the mesh of the screen is left on the screen, rotating with the screen, when the movement to the screen turning position, free fall to the dry material outlet area, and then discharge equipment.

When a few solid phase materials can not fall off freely with the rotation of the screen, the cleaning system will clean the screen in time to ensure that the screen is not blocked. The cleaned solid material is discharged to the discharge port by the cleaning system.

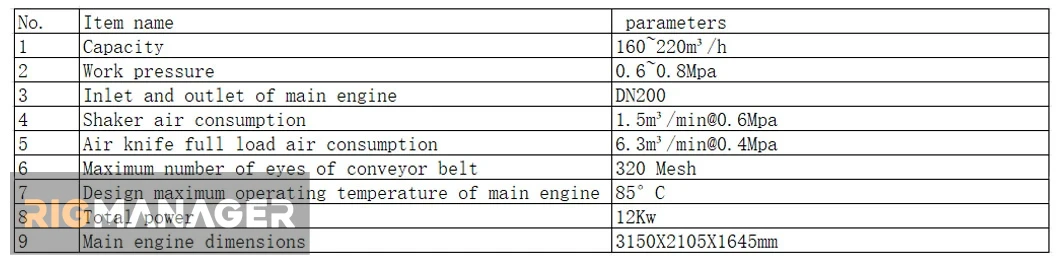

Technical parameter

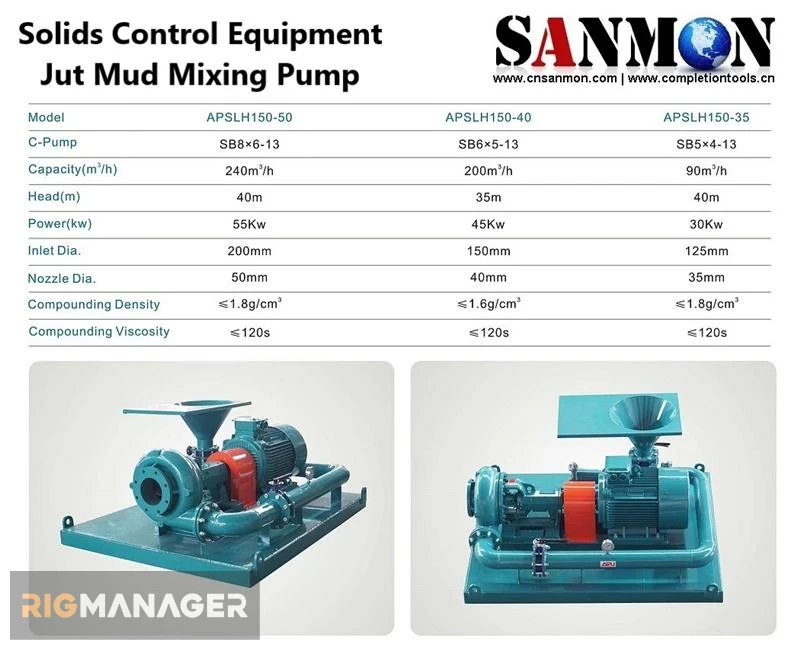

See table in attached images.

Technical advantage

1. The dual effect of vacuum adsorption and micro-excitation can strengthen the screening effect, reduce the oil content of solid phase, effectively save the cost of oil-based mud, and provide convenience for the subsequent treatment of drilling cuttings.

2. Frequency conversion control, high screening efficiency design can install a higher mesh screen, greatly reduce the burden of follow-up equipment, can be reduced from the original four solid control can be reduced to three or even two, reduce the cost of use.

3. The unique structure design can realize the simultaneous separation of solid, liquid and gas, which can replace the vacuum degasser.

Harmful gas is discharged through the exhaust port. If the harmful gas content is relatively high, it is recommended that the well team is directly connected to the ignition device through the exhaust pipe of the liquid gas separator, and discharged together.

4. The whole system does not need high excitation force, low requirements for tank surface, stable operation of equipment, low noise.

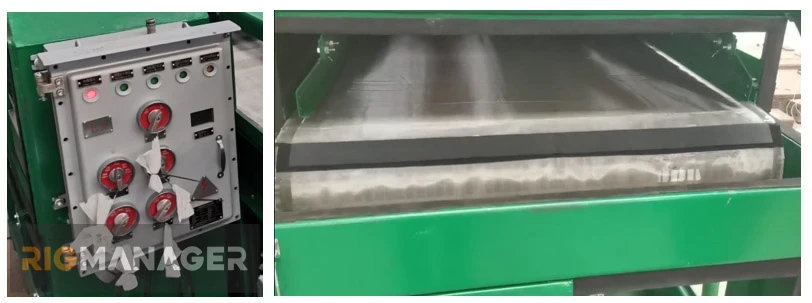

5. Fully enclosed design, the site is cleaner and easy to maintain.

6. modular removable structure, more convenient maintenance.

7. Base material cleaning system, reduce personnel maintenance.