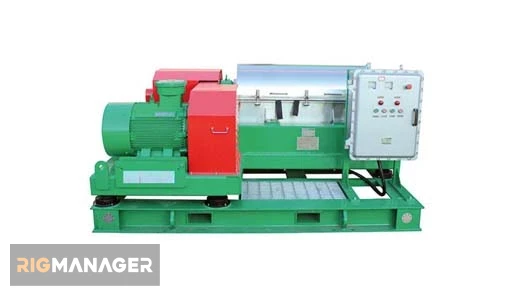

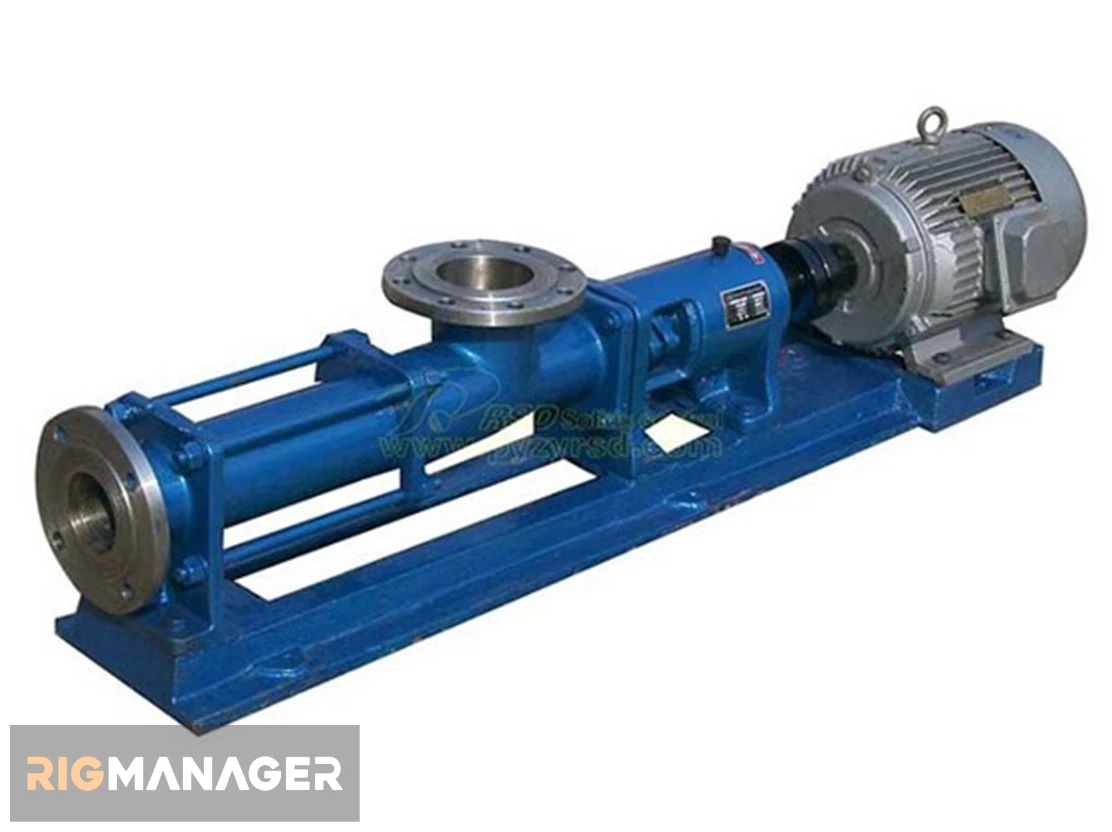

Oil drilling cuttings washing plant

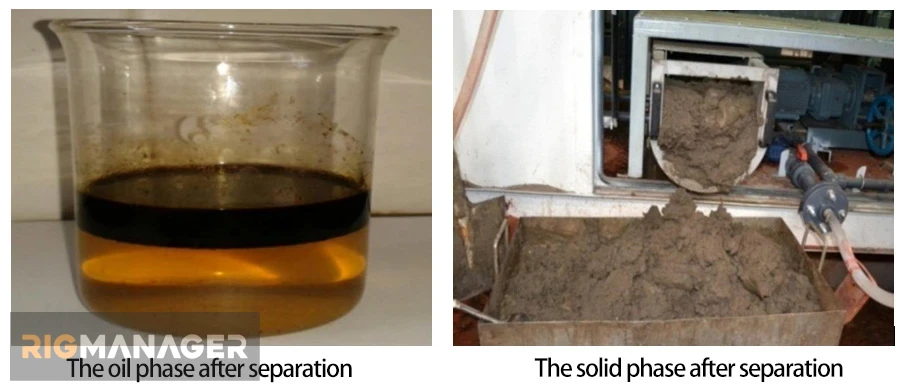

The recovered oil phase and oil phase additive are exactly the same as the original drilling fluid, with high recovery value and complete resource recycling. After treatment, the oil content of solid phase is less than 2%, and the material can be reduced. Treatment process without any harmful gas emissions, no secondary pollution; Low processing cost; High comprehensive benefits.

Summarize

The recovered oil phase and oil phase additive are exactly the same as the original drilling fluid, with high recovery value and complete resource recycling.

After treatment, the oil content of solid phase is less than 2%, and the material can be reduced.

Treatment process without any harmful gas emissions, no secondary pollution;

Low processing cost; High comprehensive benefits.

Technology advantages of Oily Cuttings adopts cleaning:

1. Simple process, mild conditions, low energy consumption.

2. The recovered oil phase has good quality and can be recycled to prepare drilling fluid.

3. Independent research and development of efficient cleaning agent, drilling cuttings to achieve standard treatment.

4. Cleaning agent can be recycled, no waste water produced in the process of treatment.

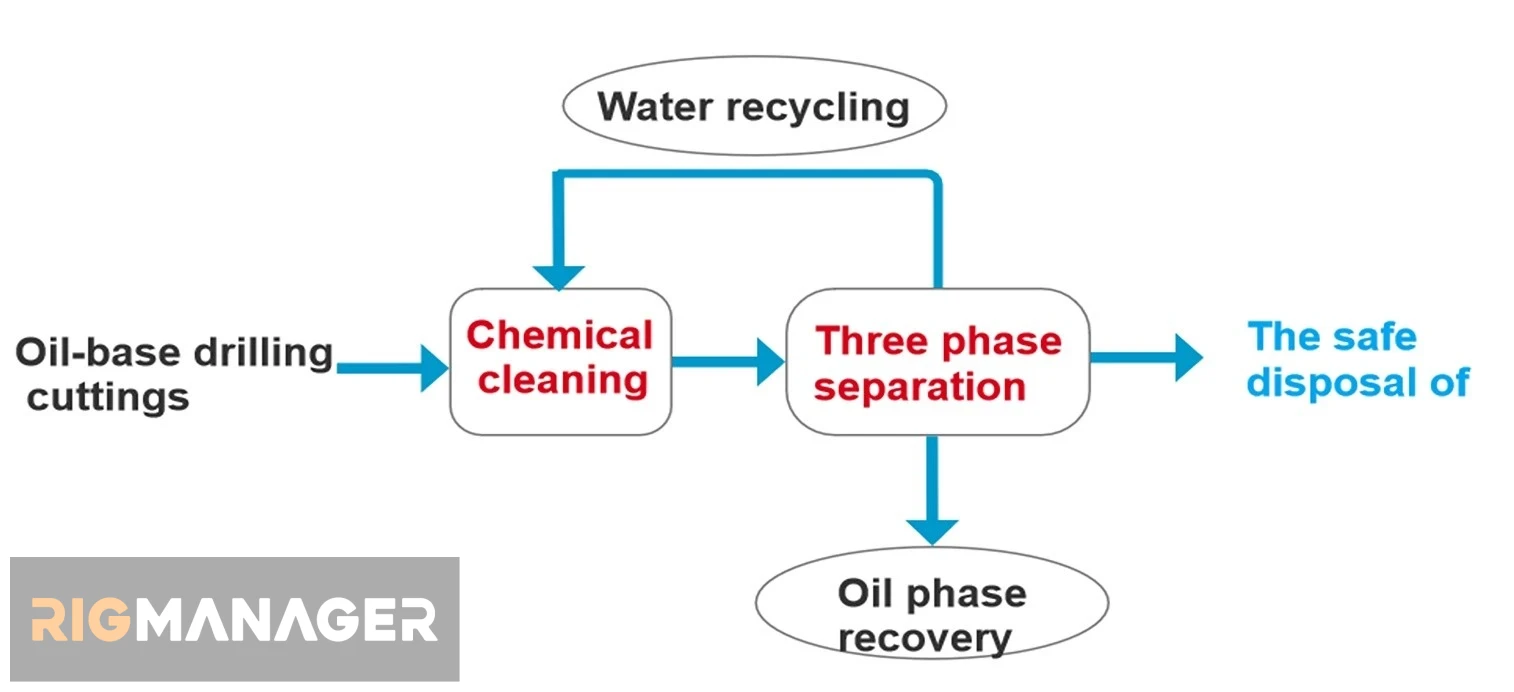

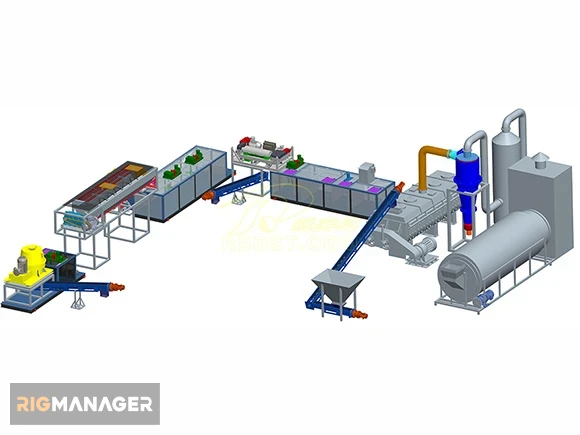

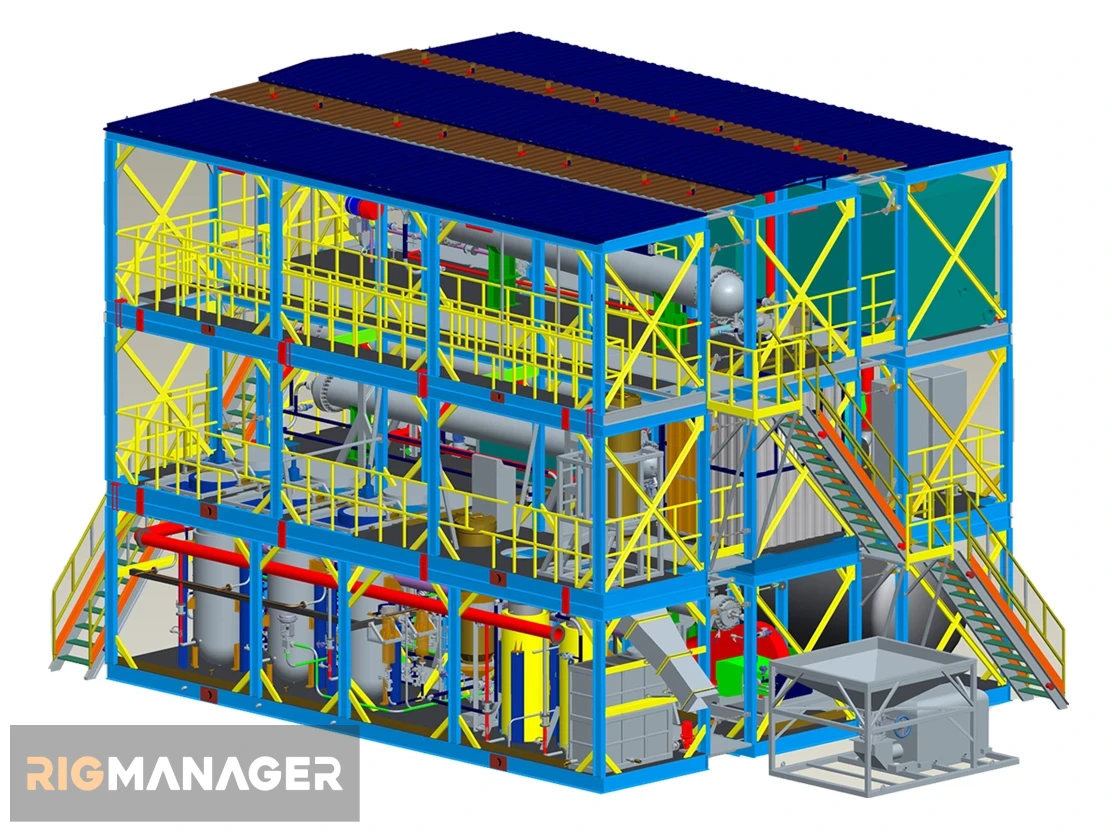

Technical Process

See chart in attached images.

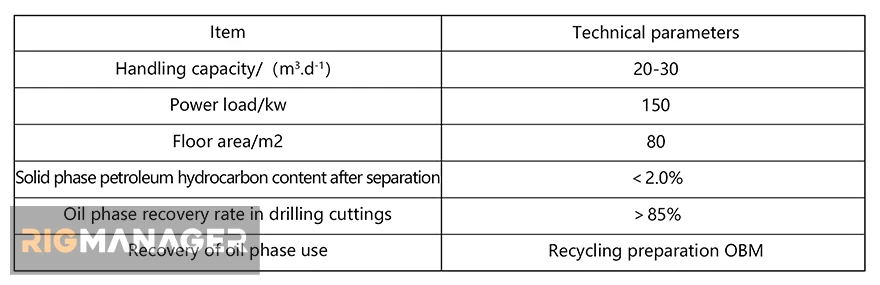

Technical parameters

See table in attached images.

Technical features

1. Self-research chemical demulsifier, cleaning agent, flocculant, separation effect is good, high efficiency.

2. The oil phase in drilling cuttings can be recovered with high efficiency (> 85%) and reused to prepare OBM.

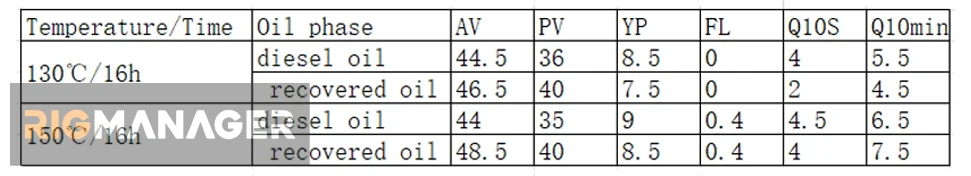

Drilling fluids were prepared with recovered oil and diesel oil respectively, and aged for 16h under the same conditions, then the main properties of drilling fluids were measured.

Indicators of oil-return matching fluid: OBM was prepared with recovered oil phase and aged at 130C and 150C for 16h, respectively. The properties of drilling fluid remained unchanged except that the apparent viscosity and plastic viscosity increased slightly.

The recovered oil phase can be used to reformulate OBM, which not only protects the environment but also saves diesel resources.

3. After oil based drilling cuttings, safe disposal (oil hydrocarbon content < 2.0%, â , solid waste of the type of phosphorus)

4. Oil-based drilling cutings were cleaned and treated as waste residue, and the main pollutants in the leached solution, PH7.92-8.35 and COD 80.5-138.7, met the requirements of â - Fe solid waste of GB18599-2001, and could be buried and safely disposed of.

5. Highly automated control system.

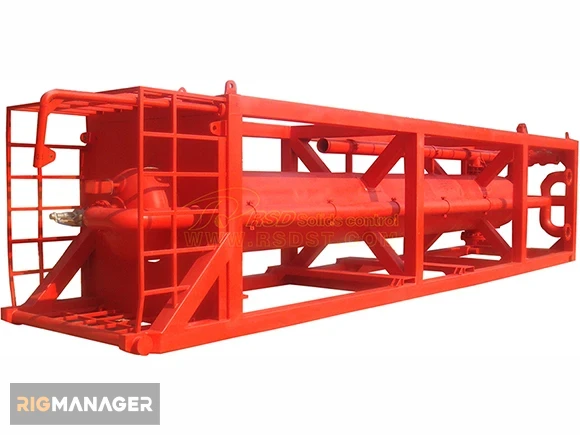

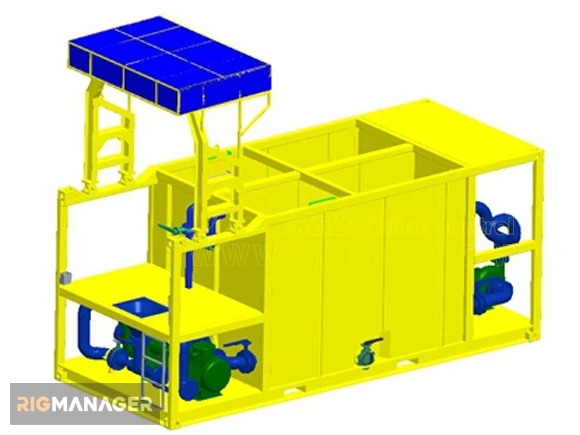

6. The core equipment is modular, and the complete set of equipment is easy to move and install