RSFC Integrated treatment technology of oily drilling cuttings oil phase recovery and environmental protection

1. The TPH content of drill cuttings after treatment is less than 0.3%;

2. Low temperature recovery of oil phase and additives, can be completely reused;

3. The oil phase recovery rate is more than 95%, and the resource utilization is complete.

Summarize

Technology comprehensive commentary:

1. The recovery rate of oil phase and oil phase additive is more than 99.7%, and the component is exactly the same as the original drilling fluid. The recovery value is high, and the resources are fully recycled.

2. After treatment, the oil content of solid phase is less than 0.3%, which can be fully used for secondary processing or discharged.

3. The treatment is a environment-friendly process without any harmful gas emissions and no secondary pollution caused.

4. Only non-polar and low polar substances are extracted. In this project, only mineral oil and oil-soluble additives are extracted, so other lithologic components are not destroyed, which is conducive to the secondary utilization of materials treated .

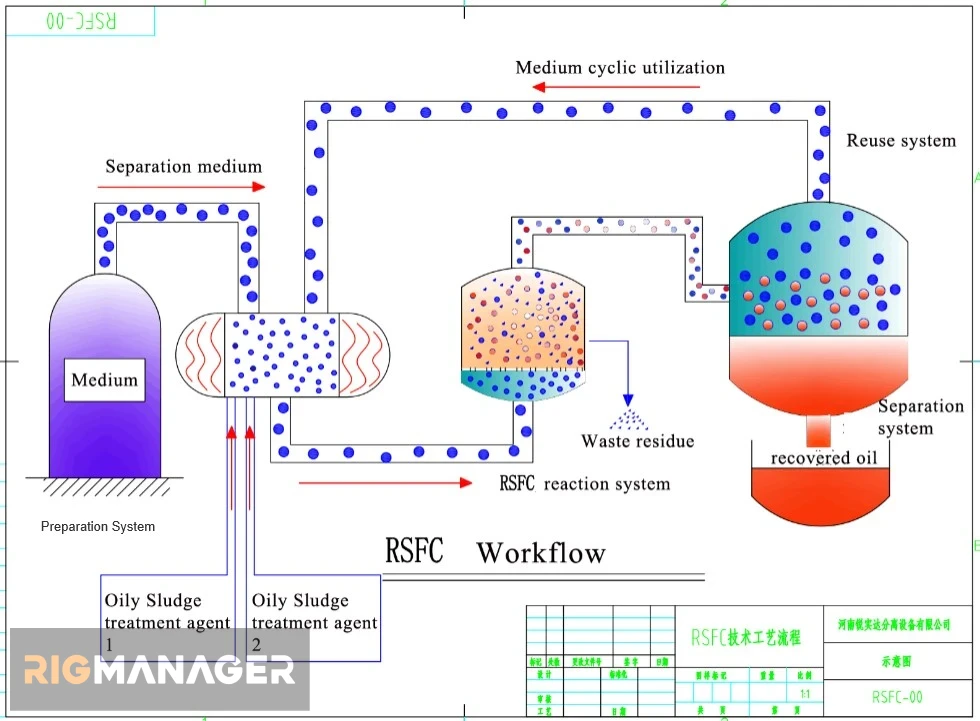

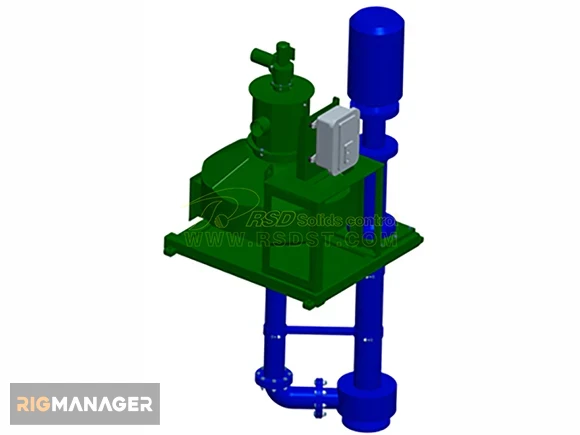

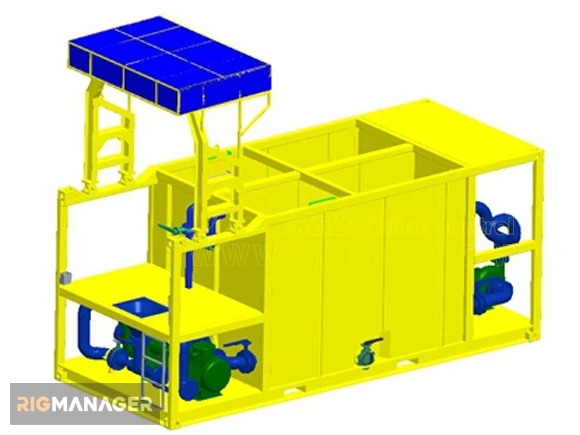

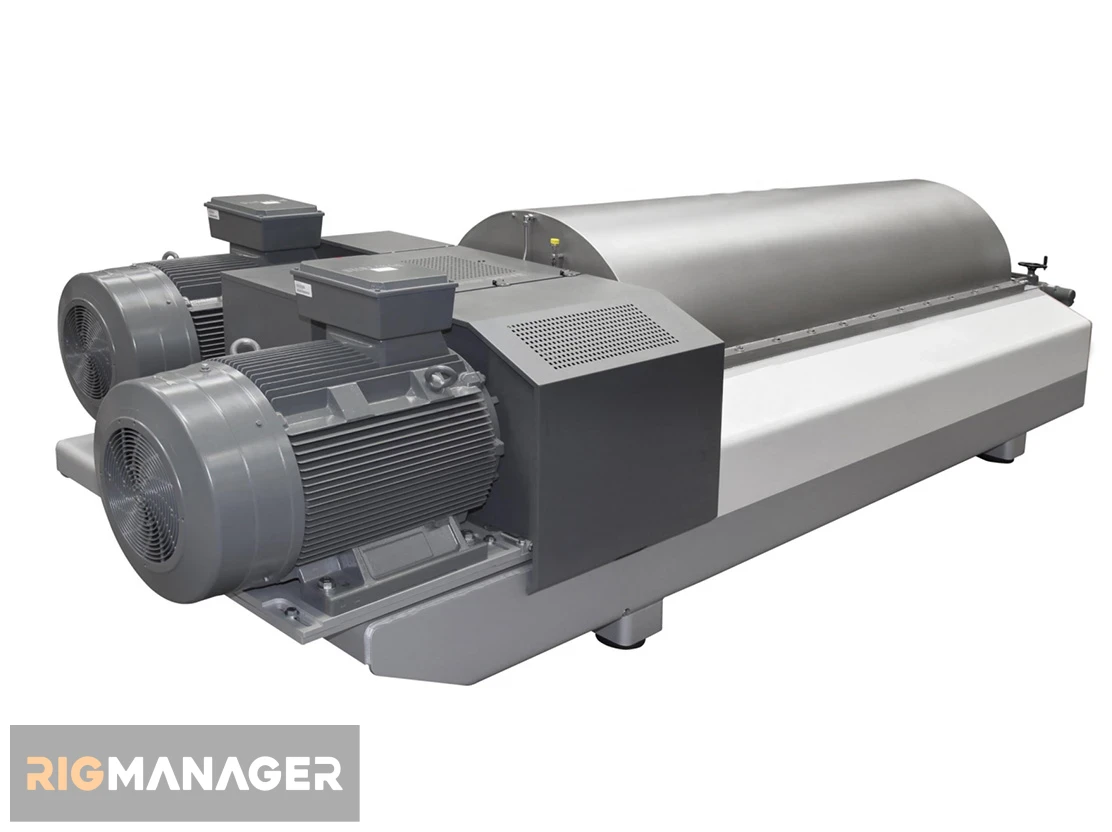

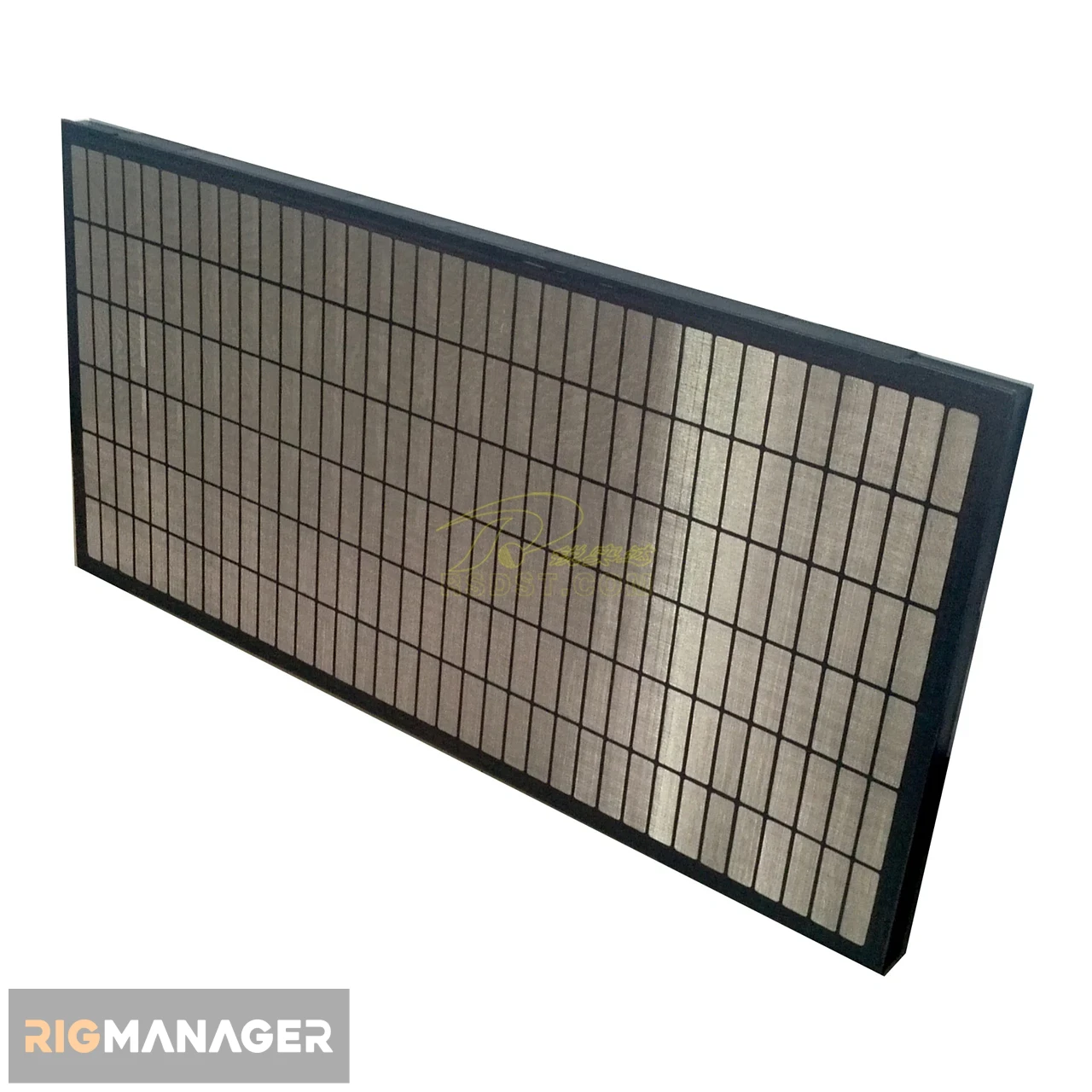

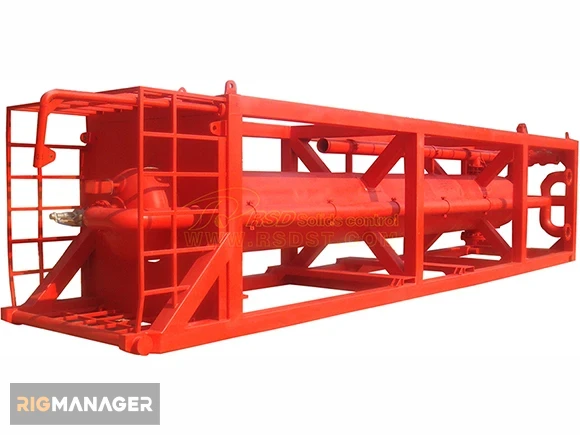

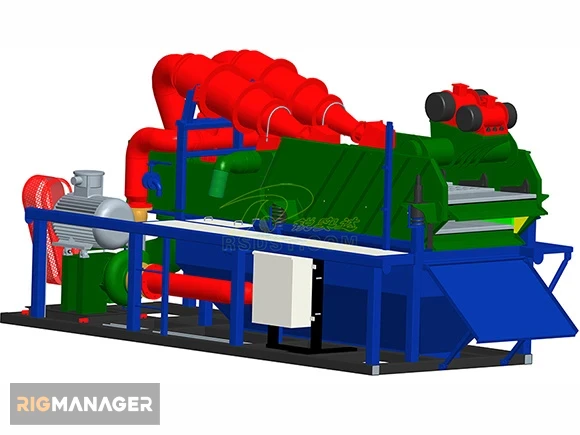

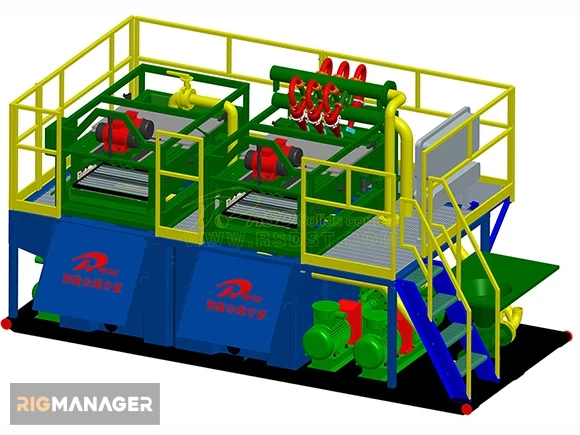

Technical process:

See chart in attached images.

General situation of oil sludge:

Oil-based mud is mainly composed of mineral oil, water, primary and auxiliary emulsifier, filtrate reducers , weighting agent and plugging material.Oily mud adheres to rock cuttings to form oily drill cuttings, which belongs to national hazardous waste. Because of the stable characteristics of oil-based mud, high viscosity and complex components, the resource utilization of oil-based mud has not been well solved.

1. Large production:one well can produce 200 ~ 300m3 oily cuttings ;

2. High oil content: high content of petroleum hydrocarbons and oil soluble mud additives;

3. Pollute water: oil directly poisons organisms, and forms oil wax to degrade water quality.

4. Pollute soil: Rainwater erosion cause oily cuttings into the soil;Oils inhibit plant growth.

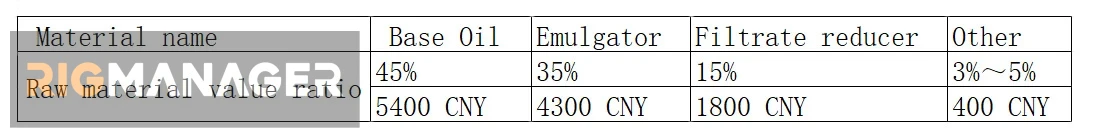

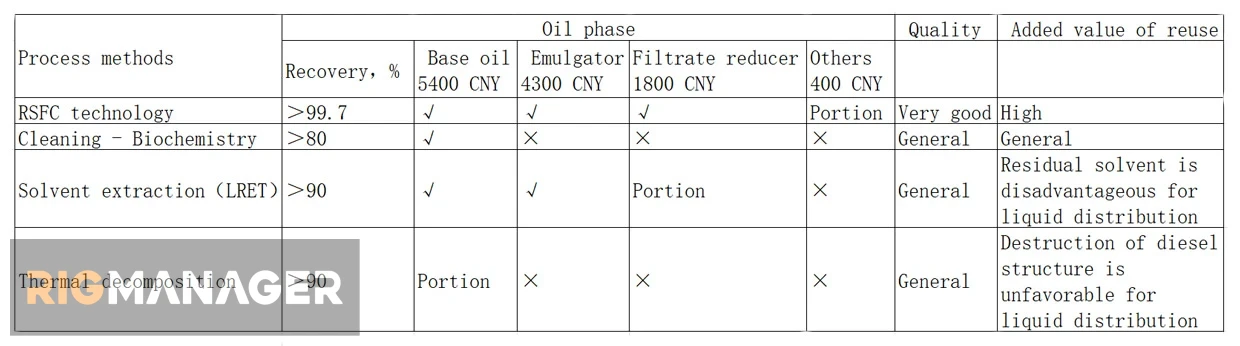

Value composition of oil-based drilling waste:

See table in attached images.

Technical features

1. The total petroleum hydrocarbon content is less than 0.3% after the treatment of oily cuttings

The TPH in the waste residue is 0.04% ~ 0.17%, which all meet the "Control Standard for Pollutants in Agricultural Sludge" (GB4284-84, TPH limit is less than 0.3%).

The residue is up to the "general pollution control standard of industrial solid waste storage and disposal site "(GB18599-2001) â , Ⅱclass solid waste technology standard. It is safe to disposal.

2. Proved by third party authority monitoring, waste residue success rate 100% of environmental protection standard.

Drilling cuttings is changed from hazardous waste to general solid waste, one step method achieves resources, reduction and harmless disposal.

3. The recovered oil phase can be fully used to prepare oil-based mud, which has high utilization rate and high added value.

OBM is prepared by recovered oil phase, which has the same performance as the new diesel oil, and can meet the needs of drilling operation.

The oil phase can directly be prepared drilling fluid, and the amount of main additives such as primary and auxiliary emulsifiers can be reduced by 50%.

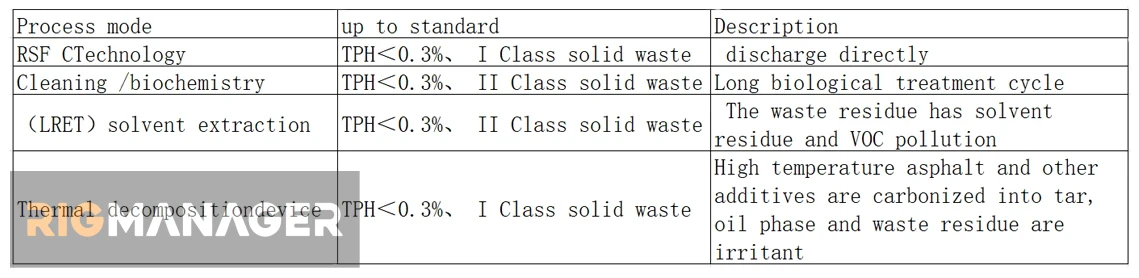

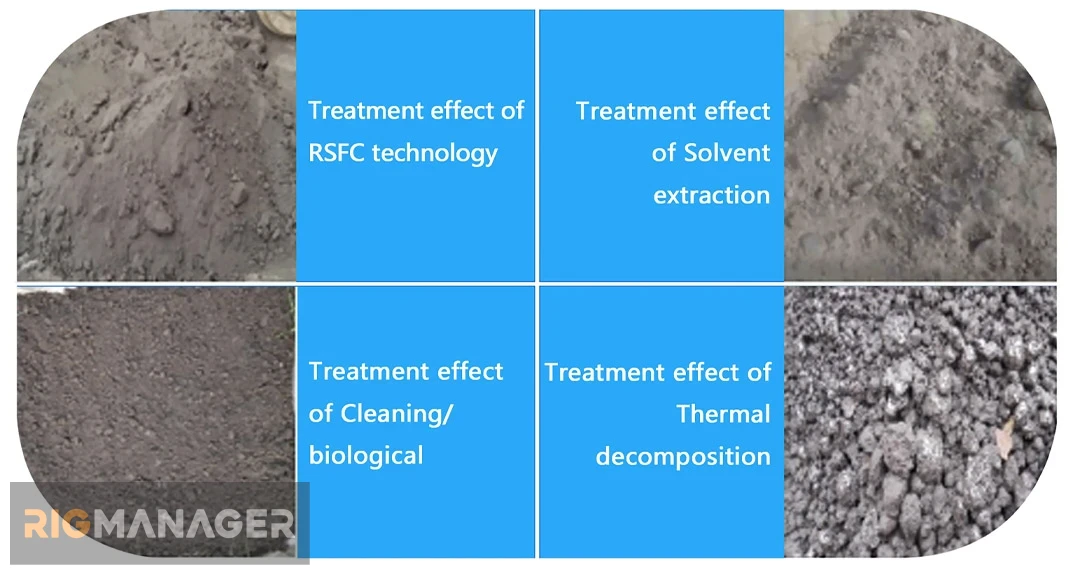

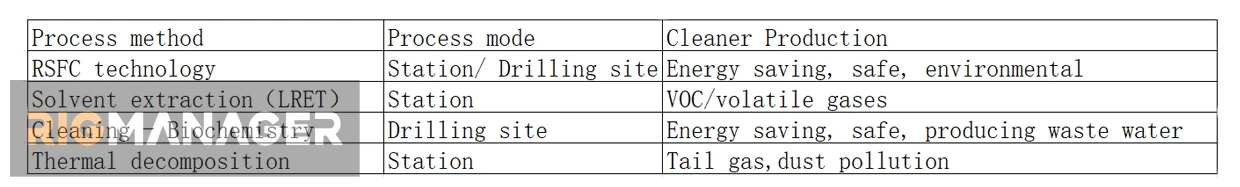

Comprehensive comparison of technology and economy with other methods:

1. All the waste residue after oil drilling cuttings treatment can reach the national standard.

2. Quality of recovered oil phase and the added value of reuse.

3. The disposal cost is moderate, the whole process is clean and environmental friendly.

Conclusion:

The research results proves that the oily drilling cuttings RSFC treatment technology has realized one-step treatment of recycling, reduction and harmless , which features with good effect, lower cost, green and environmental protection, and provides a new technology and new method for the green treatment of oil drilling cuttings.It has a broad application prospect.

Industrial application and comprehensive economy evaluation results prove that this technology has a strong market competitiveness. The economic, ecological and social benefits are remarkable through popularization and application,

The application of RSFC in the field of environmental protection of oily sludge, such as drilling cuttings, waste oil-based mud and oil-contaminated soil, will bring great economic, social and ecological benefits.

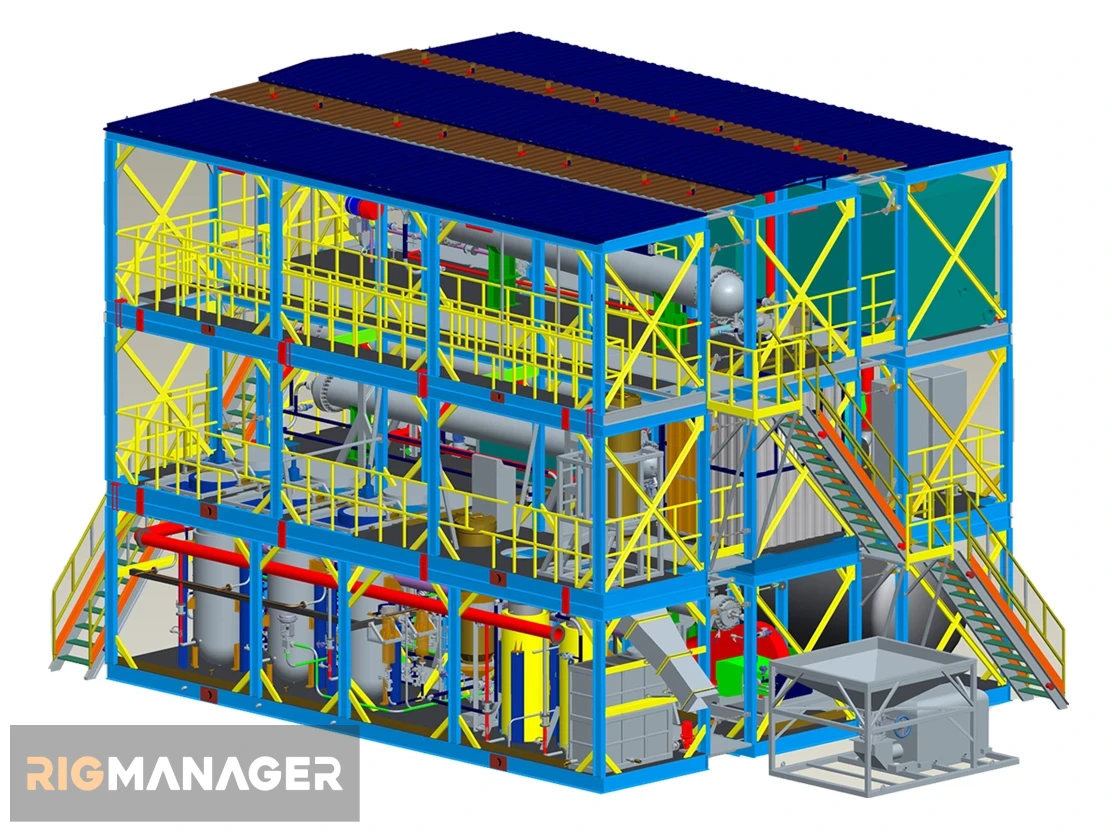

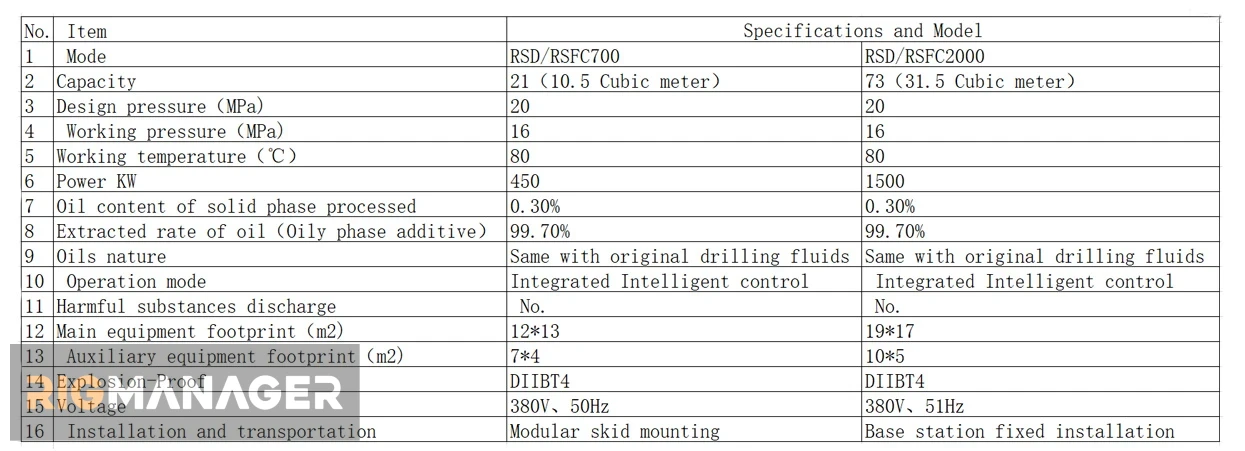

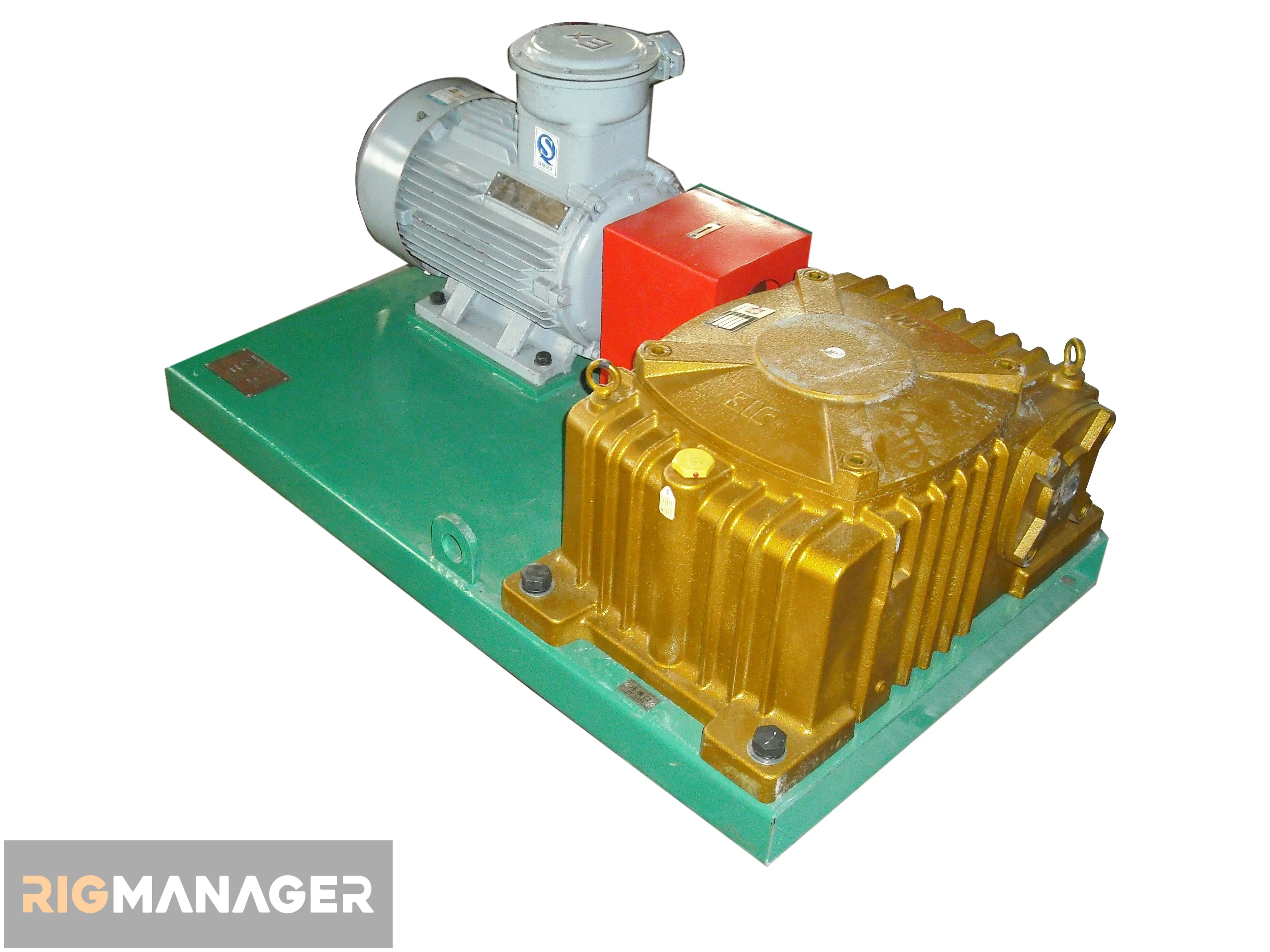

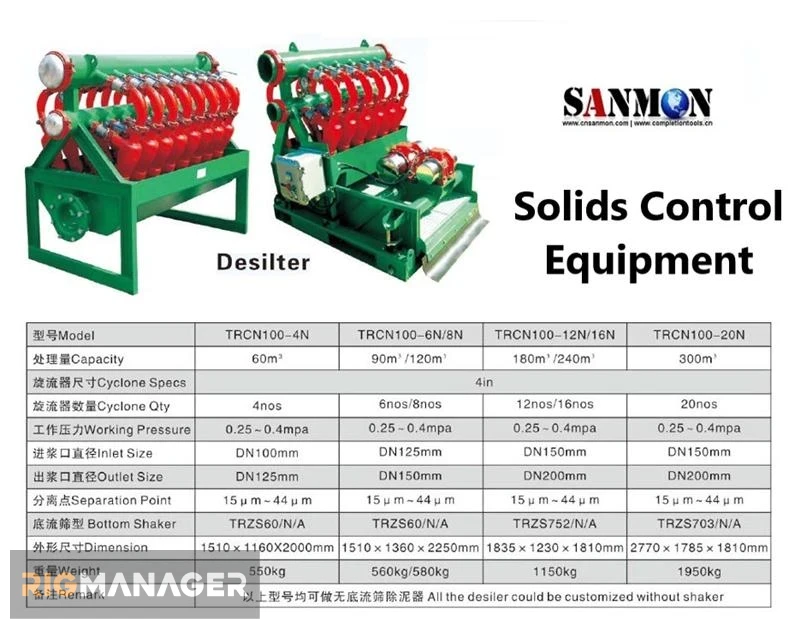

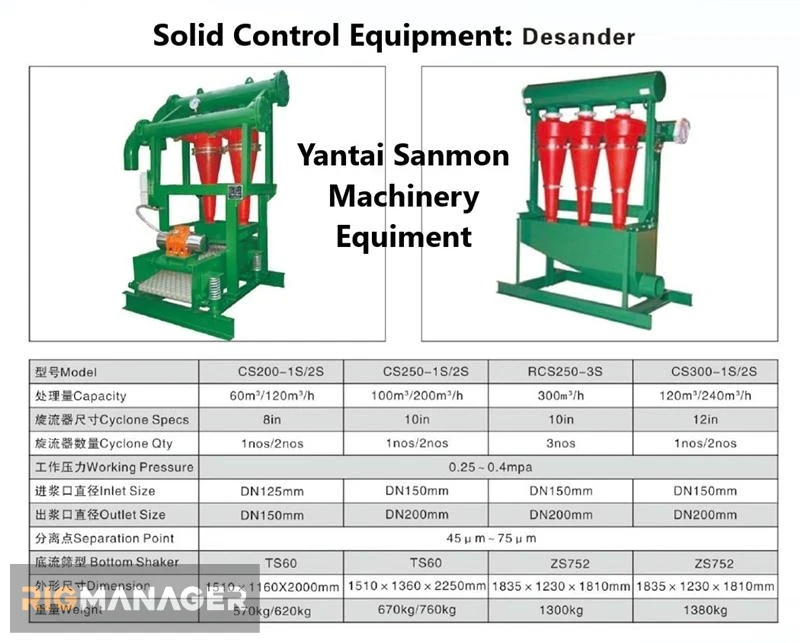

Equipment parameters

See table in attached images.